Department of Mechanical Engineering

Teaching Facilities |

|

|

| Engineering Building 1-1F |

K101 |

CAM Application Laboratory |

| K102 |

Machine Workshop |

K103

K104 |

Vehicle Dynamics Laboratory |

|

| Engineering Building 1-2F |

K201 |

Mechatronics Laboratory |

| K204 |

CAE Application Laboratory

(Computer-aided Mechanical Drawing Certification Examination Site)

(Computer-Assisted Stereoscopic

Drawing Certification Examination Site) |

| K205 |

Thermal Flow Laboratory |

|

| Engineering Building 1-4F |

K405 |

Automobile Chassis Practice Factory |

| K406 |

Automobile Engine Training Factory |

|

| Engineering Building 2-B1 |

J001 |

Vehicle Electrical Laboratory |

| J002 |

Vehicle Integrated Technology Laboratory |

|

| Engineering Building 2-1F |

J102 |

Creative Electromechanical Teaching Aids Laboratory |

|

| Engineering Building 2-2F |

J201 |

Single-Chip Microcomputer Laboratory (Single chip skills test site) |

| J203 |

Electronics Laboratory |

|

| Engineering Building 2-5F |

J501

J502 |

Precision Measurement Laboratory |

|

| Engineering Building 2-6F |

J601 |

Air Pressure Laboratory (Air Pressure Skill Certification Examination Room) |

| J602 |

Motor Laboratory |

|

| Outside the engineering

hall |

K105 |

Welding site |

| K107 |

Vehicle Maintenance Training Workshop |

|

| Cosmetics Building 1F |

B103 |

Motorcycle Training Factory |

| B103 |

Motorcycle Comprehensive Training Workshop |

|

Introduction to Mechanical Internship Factory |

| Practical Production Room Introduction |

| 1. |

This department was established to cooperate with the Ministry of

Education's key development characteristics of the vocational

education system and the cultivation of scientific and technological

education and precision manufacturing talents. The Practical

Production Room is one of the places where the department's students

take factory internship courses. It also supports the department's

teachers and students in teaching, research, experiments, etc., which

require equipment installation, parts or test piece production and

processing, as well as project services and other support work. |

| 2. |

This factory also provides equipment (machines, cutting tools, etc.)

for borrowing to assist students in special production courses and the

production and processing of simple parts that need to be processed

and assembled by themselves. This practical production studio is also

one of the training venues for mechanical processing and

manufacturing talents in the "Vehicle Parts Industry Professional

Talent Development Base", providing guidance and assistance to the

people participating in the training to acquire the professional skills

required in the workplace and to find employment smoothly after

completing the training. |

|

| Teaching objectives |

| 1. |

To cultivate students’ safe working habits and good working attitudes. |

| 2. |

Be familiar with the operation skills of various hand tools and the use

of precision measuring tools. |

| 3. |

Cultivate students’ ability to read drawings and plan processing and

manufacturing methods. |

| 4. |

Train students to be familiar with the knowledge related to machine

tool operation skills. |

| 5. |

Enable students to understand and solve process problems.

Location: Room K001, Basement of Engineering Building

|

|

| Instruments and Equipment |

| Instruments and Equipment |

Quantity |

| Hydraulic scraping table |

4 unit |

| Bench table |

6 unit |

| Drilling machine |

7 unit |

| Dust collecting grinder |

3 unit |

| Vertical sawing machine |

3 unit |

| Horizontal sawing machine |

1 unit |

| Lathe |

2 unit |

| Milling machine |

1 unit |

| Tool room |

1 unit |

|

OVERVIEW |

|

|

|

|

|

|

|

|

|

|

Introduction to CAM Application Laboratory |

| Laboratory Introduction |

| 1. |

This department was established to cooperate with the Ministry of Education's

key development characteristics of the vocational education system and the

cultivation of scientific and technological education and precision

manufacturing talents. The CAM Application Laboratory is designed to

enhance the department’s teaching and research capabilities in computer

aided manufacturing programs. At present, the construction of relevant

stamping die manufacturing technology has been completed. |

| 2. |

The main function of this laboratory is to provide a variety of computer-aided

mechanical manufacturing courses using CNC equipment and CAM related

software. Through course training, it cultivates high-end mechanical

manufacturing related talents for the industry. |

|

| Teaching objectives |

| 1. |

Be familiar with computer-aided manufacturing software and have the ability to

analyze engineering problems in the fields of material mechanics, vibration, heat

transfer, fluid mechanics, etc. |

| 2. |

Understand actual processing problems and use CAM software to establish

finished product models and manufacturing processes. |

| 3. |

Convert the results of computer simulation into CNC programs to process

various workpieces. |

|

| Instruments and Equipment |

| Instruments and Equipment |

Quantity |

| CNC machining center |

1 unit |

| CNC lathe |

1 unit |

| CNC machining center with 4th axis |

1 unit |

| CNC turning and milling machine |

1 unit |

| fine hole discharge machine |

1 unit |

| CNC Wire Cutting |

1 unit |

| Microcomputer electronic altimeter |

1 set |

|

OVERVIEW |

|

|

CNC machining center |

|

CNC lathe |

|

CNC Wire Cutting |

|

CNC machining center with 4th axis |

|

CNC turning and milling machine |

|

Fine hole discharge machine |

|

Microcomputer electronic altimeter |

|

Mechanical Training Factory - Introduction to the Machine Room |

| The machine room is one of the places where the students of our department

take factory internship courses. It also supports the teaching, research,

experiments, etc. of teachers and students in the department, which require

equipment installation, parts or test piece production and processing, as well

as project services and other support work. It also provides equipment

(machines, cutting tools, etc.) for borrowing to assist students in special

production courses and the production and processing of simple parts for self

processing and assembly. This machine room is also one of the training sites

for mechanical processing and manufacturing talents in the "Vehicle Parts

Industry Professional Talent Development Base", providing guidance and

assistance to the people participating in the training so that they can acquire

the professional skills required in the workplace and find employment

smoothly after completing the training. |

| objectives |

| 1. |

Cultivate students’ safe working habits and good working attitudes. |

| 2. |

Be familiar with the operation skills of various hand tools and the use of

precision measuring tools. |

| 3. |

Cultivate students’ ability to read drawings and plan processing and

manufacturing methods. |

| 4. |

Train students to be familiar with the knowledge related to machine tool

operation skills. |

| 5. |

To enable students to understand and solve process problems |

|

| Instruments and Equipment |

| Device Space Name |

Quantity |

| Precision high speed lathes |

16 units |

| Precision milling machines |

3 units |

| Surface grinder |

1 unit |

| Dust collecting grinder |

1 unit |

| Drilling machine |

1 unit |

| Vacuum equipment |

1 s |

|

Overview |

|

|

Precision high speed lathes |

|

Precision milling machines |

|

Surface grinder |

|

Dust collecting grinder Dust collecting grinder |

|

Drilling machine |

|

Vacuum equipment |

|

Introduction to the Mechatronics Integration Laboratory |

| Laboratory Overview |

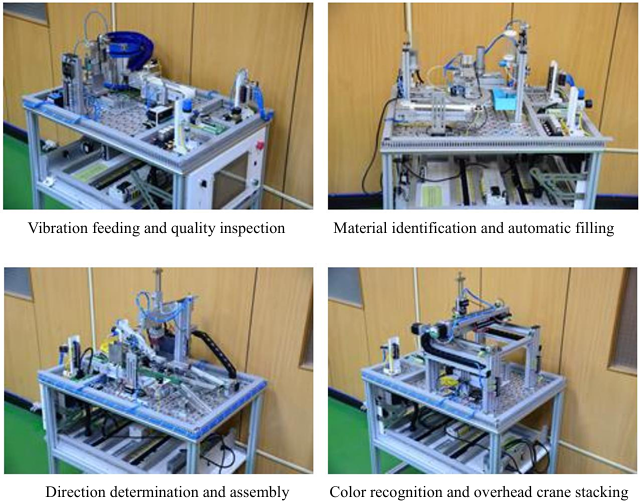

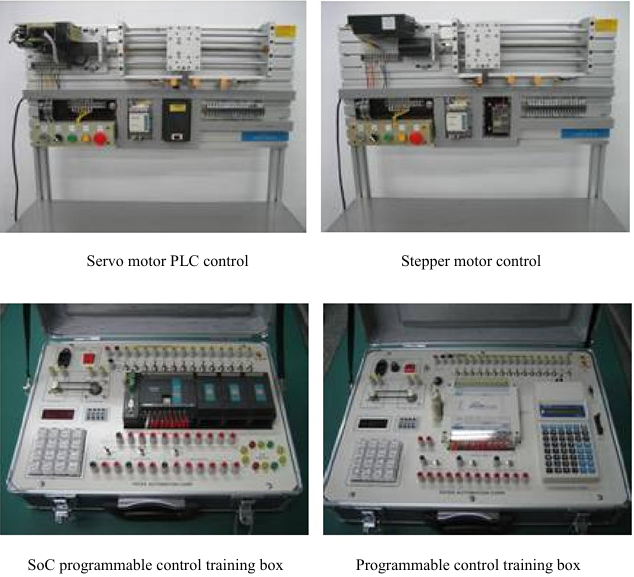

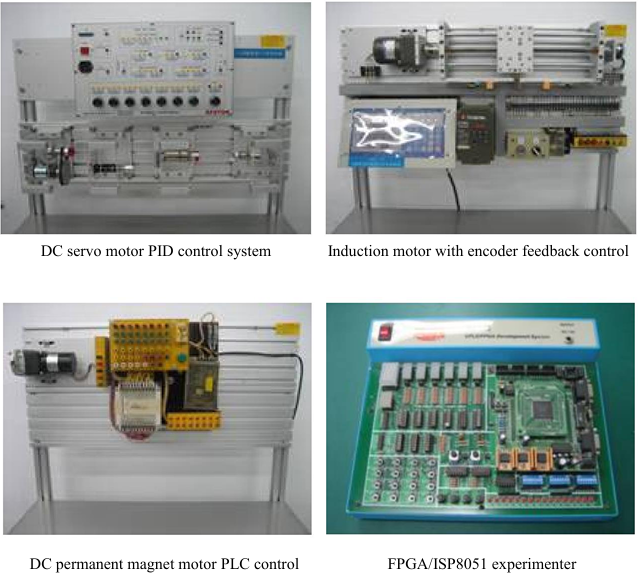

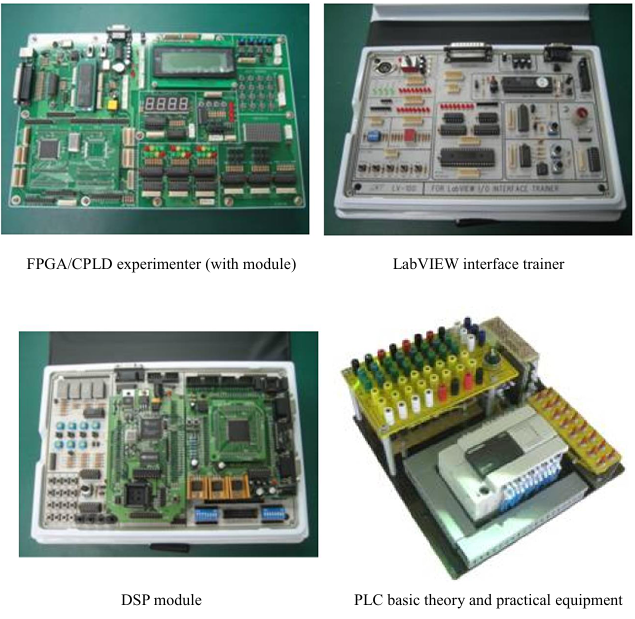

| This laboratory is an elective course for junior and senior students in the department, aimed at cultivating talent in the field of mechatronics integration. The main equipment includes: |

| • |

Vibration feeding and quality inspection |

| • |

Material identification and automatic filling |

| • |

Direction determination and assembly |

| • |

Color recognition and overhead crane stacking |

| • |

Automated warehousing and direction switching |

| • |

Shape recognition and conveyor inspection station |

| • |

Color recognition and posture adjustment inspection station |

| • |

Posture determination and switching inspection station |

| • |

Material sorting and processing inspection station |

| • |

Hydraulic punching and forming inspection station |

| • |

Programmable control training boxes |

| • |

LabVIEW interface trainers |

| • |

FPGA/CPLD experimenters (with modules) |

| • |

Silent air compressors and air tanks |

| • |

FPGA/ISP8051 experimenters |

| • |

Psoc System-on-Chip experimenters |

| • |

DSP modules |

| • |

Programmable motor control application platforms |

| • |

Motion Chip II |

| • |

MCK digital brushless motor control teaching modules |

|

| Teaching objectives |

| 1. |

This laboratory mainly focuses on mechatronics integration, motor control, and logic design.

The goal is to introduce a variety of control systems such as servo systems, motor control system

applications, and PLC applications. |

| 2. |

The lab was established to align with the program curriculum, utilizing existing equipment to

train senior students in preparation for the national Class C Mechatronics Technician

Certification. It aims to cultivate students with both practical and research capabilities. |

| 3. |

The lab supports courses such as "Automation Practice", "PLC Programmable Control",

"Pneumatic Control and Experimentation", "Hydraulic and Pneumatic Practice", and

"Mechatronics Integration". It uses the available equipment to prepare students for the national

Class C Mechatronics Certification, fostering a blend of hands-on skills and academic research

ability. |

|

Laboratory Location

Room K201, 2nd Floor, Engineering Building I. |

Supervising Professor

Chih-Yi Chang |

Full Laboratory View |

|

Equipment List |

|

|

|

|

|

| Lab Projects |

| 1. |

PLC motor control practice |

| 2. |

PLC training box simulation practice |

| 3. |

Mechatronics automation application |

| 4. |

Servo motor control practice |

| 5. |

Logic design practice |

| 6. |

LabVIEW graphical control practice |

|

Introduction to the CAE Applications Laboratory |

| Laboratory Overview |

| In recent years, with the rapid advancement of computer technology, the demand for

professionals skilled in computer-aided design, manufacturing, and analysis has become urgent,

particularly as traditional industries face the need for upgrades and full-scale digitalization. Taiwan,

in particular, is transitioning from a manufacturing-based industry to one focused on research and

design. Accelerating product development through computer technology has become an essential task

across all industries. |

| This laboratory is primarily intended to support computer-aided engineering (CAE) and

computer-aided design (CAD) coursework. Through these courses, the lab helps cultivate product

development talent for industry. |

| The lab is also an official testing site for the Class B and C certification exams in "Computer

Aided Mechanical Design and Drafting" and Class C in "Computer-Aided 3D Drafting." It is fully

equipped with the latest software and hardware to meet certification requirements and offers

preparatory courses to assist students in obtaining certifications. The number of successful candidates

continues to increase each year. |

| Teaching Objectives |

| 1. |

Gain proficiency in computer-aided engineering analysis software and develop the ability to

analyze engineering problems in areas such as mechanics of materials, vibration, heat transfer,

and fluid mechanics. |

| 2. |

Understand practical engineering problems and use software to build analytical models and

workflows. |

| 3. |

Use computer simulations to verify theoretical knowledge learned in various disciplines. |

|

| Laboratory Location |

| Room K204, 2nd Floor, Engineering Building I. |

| Supervising Professor |

| Professor Chih-Yi Chang |

| Equipment List |

| Equipment Name |

Quantity |

| Intel Core i7-10700 desktop PC (22" LCD monitor, 32GB RAM, 512GB

SSD, 1TB HDD, NVIDIA Quadro P1000 graphics card, system restore

card) |

51units |

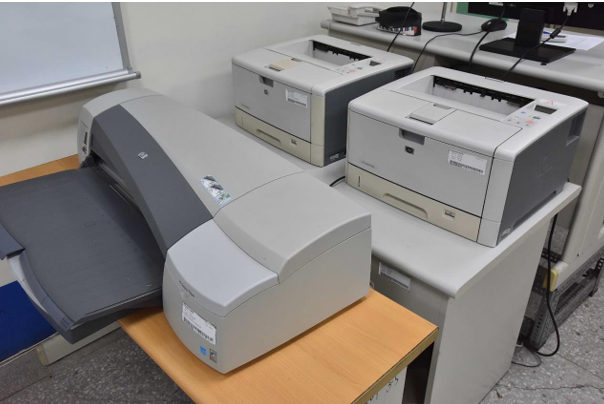

| A3 Network Laser Printer (HP LaserJet M42625dn) |

1 units |

| A3 Network Laser Printer (HP LaserJet 5200L) |

1 unit |

| A2 Network Inkjet Plotter (HP Designjet 110 plus) |

1 unit |

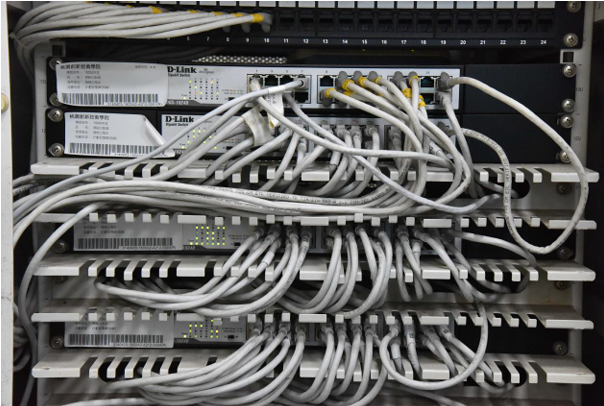

| Network Cabling (including rack and switch) |

1 set |

| Monitoring System Software (Broadcast Teaching) Monitoring System

1 set

Software (Broadcast Teaching) |

1 set |

| UPS Uninterruptible Power Supply + Voltage Regulator (25KW) |

1 set |

|

Equipment List |

|

|

A2 inkjet plotter and A3 laser printer

|

|

UPS and voltage regulator |

|

Switch-type network hub

|

|

| Software & Courses Offered |

| No. |

Software |

Licenses |

Related Courses |

| 1 |

Inventor Professional 2021 |

100users |

Computer-Aided Drawing (required)

Inventor 3D Drawing (elective)

3D CAD (elective)

Mechanical CAD (elective)

Class C and B exam prep courses |

| 2 |

AutoCAD 2021 |

100users |

Mechanical Drawing (required) |

| 3 |

COMSOL Multiphysics 3.5a |

60users |

Computer-Aided Engineering Analysis (elective) |

| 4 |

SolidWorks 2019 |

60users |

Computer-Aided Drawing (required)

SolidWorks 3D Drawing (elective)

Advanced Drawing (elective) |

| 5 |

CATIA V5R21 (Education Edition) |

20users |

CATIA 3D Drawing (elective) |

| 6 |

MasterCAM 2020 (Education Edition) |

60users |

Programming and Cutting Tools (elective) |

| 7 |

MATLAB 7.0 |

100users |

Numerical Analysis (elective)

Engineering Applications of MATLAB (elective) |

| 8 |

CyberLink PowerDirector 18 |

60users |

Digital Video Editing (elective) |

|

Introduction to the Thermo-Fluid Laboratory |

| Laboratory Overview |

The purpose of this laboratory is to train beginners in thermo-fluid experimental techniques and to

inspire research-oriented thinking in students, enabling them to validate theory through practical

experimentation. The goal is to help students gain a more accurate, in-depth, and concrete

understanding of thermal-fluid sciences.

This laboratory is particularly focused on providing students with experimental knowledge and skills

in thermodynamics, fluid mechanics, fluid machinery, and green energy. In addition to experiments

related to thermal and fluid systems, green energy systems such as fuel cells, solar power, and wind

power are also included, making the experiments both practical and comprehensive.

The lab is suitable for a semester-long course (2–3 hours per session), and the experiments are divided

into three major categories: |

| 1. Thermal Experiments: |

| • |

Heat exchanger test |

| • |

Heat conduction experiment |

| • |

Fire point test |

| • |

ASTM distillation test |

| • |

Viscosity test |

| • |

Calorific value measurement |

|

| 2. Fluid Mechanics and Fluid Machinery Experiments: |

| • |

Flow meter test |

| • |

Pump performance test |

| • |

Venturi tube experiment |

| • |

Pipeline friction loss test |

| • |

Wind tunnel test |

|

| 3. Green Energy Experiments: |

| • |

Fuel cell test |

| • |

Wind energy training system |

| • |

Solar energy experiment |

|

| Teaching Objectives |

| 1. |

To cultivate students' skills in thermal, energy, fluid mechanics, and fluid machinery experiments,

and to inspire research-based thinking by connecting theory and practice. Students will gain a

solid foundation in thermodynamics, heat transfer, and fluid mechanics through this integration. |

| 2. |

Each experiment is designed to be comprehensive yet easy to understand. The course proceeds in

a step-by-step manner, beginning with the objective and theoretical background, followed by

detailed steps and designed data sheets. This ensures students can accurately observe, record, and

analyze experimental results, and reflect on the findings to develop structured and practical

knowledge. |

| 3. |

Students are expected not only to understand the experimental principles and procedures but also

to analyze the discrepancies between data and theory and identify possible sources of error. |

|

| Laboratory Location |

| Room K205, 2nd Floor, Engineering Building I. |

| Supervising Professor |

| Professor Chih-Yi Chang |

| Laboratory Equipment |

| Thermal Experiment Equipment |

| No. |

Equipment Name |

Devices Used |

| 1 |

Heat Exchanger Experiment |

HEX-300E Water-to-water exchanger, thermometer,

flow meter |

| 2 |

Heat Conduction Measurement |

ET100 apparatus, temperature controller, timer, digital

thermometer |

| 3 |

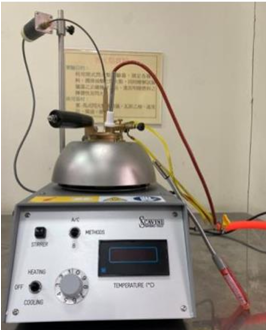

Calorific Value Measurement |

PARR 1341 Calorimeter, high-pressure oxygen tank,

precision balance, ignition device |

| 4 |

Fire Point Test |

Closed flash point tester, gas cylinder, thermometer,

kerosene, diesel |

| 5 |

ASTM Distillation Test |

Wind shield, cooling bath, condenser tube, distillation

flask, thermometer, measuring cylinder, unleaded

gasoline |

| 6 |

Viscosity Test |

Saybolt viscometer, rotational viscometer |

|

| Fluid Mechanics Equipment |

| No. |

Equipment Name |

Devices Used |

| 1 |

Venturi Tube Test |

TQ-H5 Venturi setup, hydraulic bench |

| 2 |

Flow Measurement Test |

TQ-H10 Flow meter, hydraulic bench |

| 3 |

Pipeline Head Loss Test |

TQ-H34 Loss experiment setup, hydraulic bench |

| 4 |

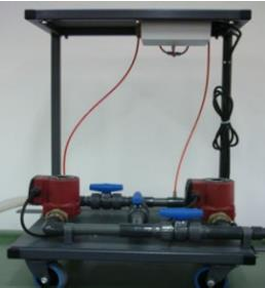

Pump Performance Test |

TQ-H32 Pump test setup (parallel/series), hydraulic

bench |

| 5 |

Valve Characteristics Test |

Valve test bench, coupler |

| 6 |

Reynolds Number Experiment |

Glass tubes, heating unit, Reynolds apparatus |

| 7 |

Wind Tunnel Test |

Wind tunnel, motor, data acquisition system |

|

| Green Energy Experiment Equipment |

| No. |

Equipment Name |

Devices Used |

| 1 |

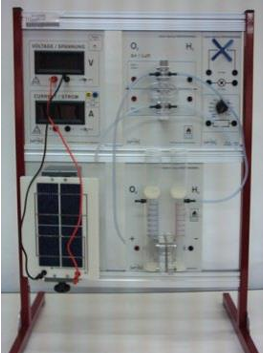

Fuel Cell System Test |

Solar module, electrolyzer, fuel cell, load module,

measurement module, analysis software |

| 2 |

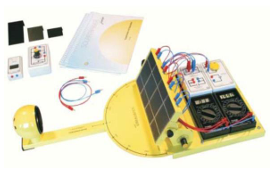

Solar Power Module |

IKS solar training platform, solar panels, shading

panels, multimeters, sensors, radiation simulators,

batteries, loads |

| 3 |

Wind Power Module |

IKS wind training platform, wind box, anemometer,

multimeters, axial turbine components, blades,

batteries, loads |

|

Lab Overview Photos |

|

|

|

|

| Main Equipment and Experiment Objectives |

| Thermal Experiment Equipment |

| No. |

Experiment Objectives |

| 1 |

Heat Exchanger Experiment

Different flow configurations are used to

allow fluids at different temperatures to

flow through a double-pipe heat

exchanger. Students measure the heat

transfer rate, thermal conductivity, and

temperature distribution, and compare

heat transfer efficiency across conditions. |

|

| 2 |

Heat Conductivity Measurement

Using a thermal conductivity apparatus,

students measure the thermal conductivity

coefficients of various materials. |

|

| 3 |

Calorific Value Measurement

Calorific value refers to the heat released

from burning 1 gram of fuel. Typically

measured using a calorimeter, this

experiment employs an adiabatic

calorimeter to determine the calorific

value of solid or liquid fuels. |

|

| 4 |

Fire Point Test

A closed cup flash point tester is used to

measure the flash points of various fuels

and lubricants. Students also learn the

correct operation of testing instruments

and understand fuel volatility and flash

points. |

|

| 5 |

ASTM Distillation Test

Using ASTM standard distillation

equipment, this experiment obtains the

evaporation curve of engine fuel to

evaluate its purity and volatility, serving

as a reference for fuel quality control. |

|

| 6 |

Viscosity Test

• The Saybolt viscometer measures the

time required for oil to flow through a

standard orifice at a set temperature,

indicating viscosity.

• A rotational viscometer is also used to

measure viscosity, allowing

comparison and validation of results

obtained from both instruments. |

|

|

| Fluid Mechanics & Fluid Machinery Equipment |

| No. |

Experiment Objectives |

| 1 |

Venturi Meter Test

Tests the relationship between velocity

and pressure at various sections of a

Venturi tube and calculates the flow

coefficient by comparing theoretical and

actual flow rates. |

|

| 2 |

Flow Measurement Test

Introduces the principles and usage of

various flow meters including Venturi

meters, orifice plates, and rotameters.

Students explore the relationship between

flow coefficients and Reynolds numbers. |

|

| 3 |

Head Loss Test of Pipeline

Investigates energy losses caused by fluid

viscosity, pipe wall roughness, and

velocity changes as water flows through

pipelines and fittings. Helps students

understand key design considerations in

piping systems. |

|

| 4 |

Pump Performance Test

Measures flow rate, total head, and

efficiency of centrifugal pumps at

different speeds. Students create

performance curves and examine how

series or parallel pump configurations

affect performance. |

|

| 5 |

Valve Characteristic Test

Measures pressure drop across five types

of valves—check, gate, ball, plug, and

angle—under different flow rates to

determine geometric loss coefficients for

design and application reference. |

|

| 6 |

Reynolds Number Experiment

Measures flow rate in a circular pipe and

uses dye to visualize the differences

between laminar and turbulent flows.

Helps students understand and determine

the critical Reynolds number for flow

transition. |

|

| 7 |

Wind Tunnel Test

Small-scale models (e.g., trains, cars,

aircraft, wings) are placed in a wind

tunnel to measure flow velocity and drag

force. Students calculate drag coefficients

(Cd) for real objects under various speeds. |

|

|

| Green Energy Equipment |

| No. |

Experiment Objectives |

| 1 |

Fuel Cell System Test

This experiment explores the process of using

solar panels to power an electrolyzer that

produces hydrogen and oxygen. These gases are

then used in a fuel cell, which generates

electricity through electrochemical reactions to

power loads like bulbs, motors, or model cars.

Students determine the electrolyzer’s

performance curve, efficiency, and analyze the

series/parallel configuration effects on the fuel

cell system. |

|

| 2 |

Solar Power Module

Solar cells convert sunlight directly into

electricity using the photoelectric effect.

Students use the IKS solar training platform to

assemble modules and conduct experiments

including:

•Open-circuit voltage and short-circuit

current under various shading

conditions

• Series and parallel configurations

• I-V characteristics under different

illumination levels

•Maximum power point and efficiency

evaluations |

|

| 3 |

Wind Power Module

This module converts wind energy into

mechanical energy by rotating wind turbine

blades. A speed increaser boosts the rotation

rate to drive a generator. The generated AC

voltage is then regulated and converted into DC

power stored in batteries. |

|

|

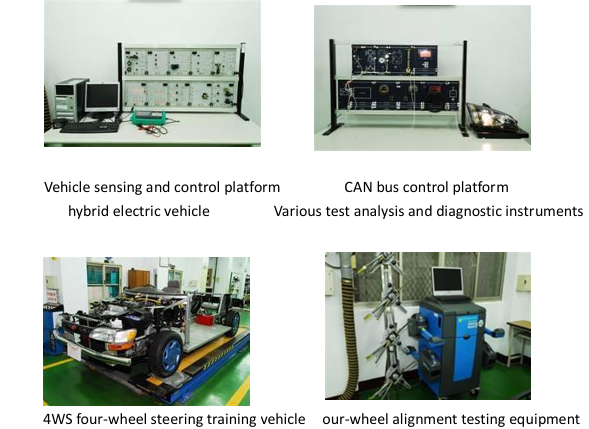

Vehicle Electrical Laboratory |

| Introduction: |

| This laboratory is the venue for the vehicle engineering internship courses

(II III IV V) for the vehicle engineering group students of our department. It

also supports the teaching, research, and experiments of teachers and students in

the department, as well as the construction and education cooperation project

services. |

| Objectives: |

| Establish students' understanding of advanced vehicle electronic motor control

applications in various vehicle systems including vehicle sensing control, CAN

network |

| The technology of road control, hybrid electric vehicle control, body circuit, air

conditioning, steering positioning, etc. has theoretical concept verification |

| The training provides students with practical experience in diagnosis and

maintenance, so as to train them to become maintenance engineers of advanced

vehicles, or to become research engineers. |

| Design engineer. The work of this laboratory is mainly devoted to the following four

points: |

| 1. |

Planning and implementation of vehicle maintenance education, training,

certification and competition. |

| 2. |

Research, develop and produce vehicle engineering education and training

equipment, handouts and manuals. |

| 3. |

Provide technical support and experience consultation for advanced diagnostics of

various vehicle systems. |

| 4. |

Vehicle system components, performance testing and analysis.

Overview |

|

| Overview |

|

| Instruments and Equipment |

| The automotive electrical system laboratory is equipped with vehicle sensing and

control demonstration platform, CAN bus control demonstration platform, hybrid

electric vehicle, computer-controlled engine demonstration platform, body circuit

demonstration platform, central locking demonstration platform, automobile air

conditioning demonstration platform, automatic constant temperature air

conditioning demonstration platform, various test analysis and diagnostic

instruments, 4WS four-wheel steering training vehicle, and four-wheel alignment

detection equipment. |

|

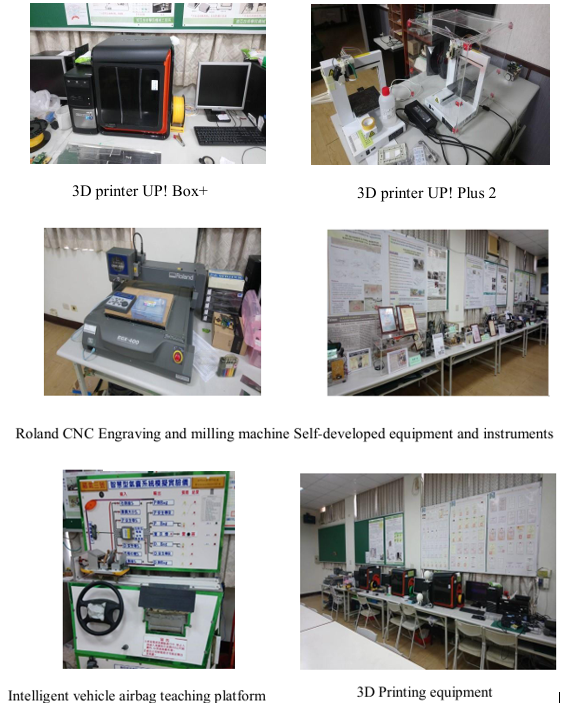

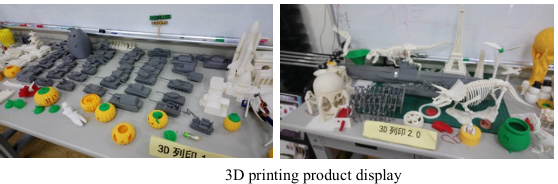

Creative M&E Teaching Aids Laboratory |

| Laboratory Profile: |

| The "Creative Electromechanical Teaching Aids Laboratory", which attaches equal importance

to teaching and research, practice and production, is also the listing office and one of the main R&D

bases of the "Electromechanical Power System and Micro Molding Technology R&D Center" of the

Department. In addition to teaching and R&D, the laboratory has three functions: |

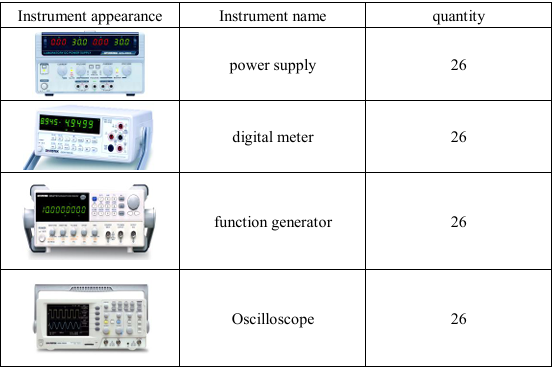

| 1. |

For the special finished product display and display of electromechanical power and 3D

printing of the department. |

| 2. |

For the production and venue of the Department's practical topics and the construction of

competition simulation venues. |

| 3. |

It is a research room for teachers, students and graduate students of the Department's special

research and development projects |

|

| In short, this laboratory is a multi-functional purpose, which can be used for practical

production courses in mechatronics and 3D printing, and when necessary, it can be used as a

production and maintenance base for external competitions and a display venue for thematic

finished products. |

| Teaching Objectives: |

| Creativity is not limited to men and women, young and old, and school experience, you can get

good creative ideas at any time around your life, and then put practical ideas into concrete practice,

which can become inventions. Good ideas must be commercialized to be shared by human beings,

and the process of commercialization must be realized by mechatronics engineering and 3D printing

technology |

| 1. |

Familiarity with the laws of creativity; |

| 2. |

cultivating creative crafts; |

| 3. |

Combined with 3D printing skills: |

| 4. |

Applied Mechatronics Engineering Techniques: |

| 5. |

Produce creative 3D printing works combined with mechatronics. |

|

| A full view of the laboratory |

|

| Instruments and equipment |

| In terms of instruments and equipment, the laboratory has 3D printers, CNC engraving and

milling machines, digital oscilloscopes, high-speed CCD cameras, and various single-chip

simulationsIn addition to the research equipment such as burners, there are also professional sheet

metal processing areas, circuit board production areas, electronic circuit welding testing areas and

parts and material warehouses, supplemented by the latest mechanical and electronic drawing and

wiring software, so that the center can design, produce and assemble one-stop research and

development tools, environment and capabilities, so whether it is teaching or research, it can fully

meet the needs of teachers and students of the department. |

|

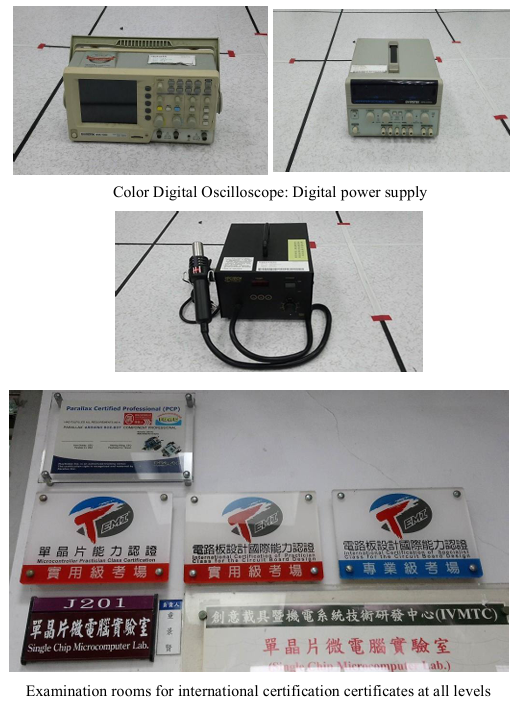

Single-chip microcomputer laboratory |

| Laboratory Profile: |

| A single chip is a single chip that integrates the CPU, memory, and I/O ports of a computer

into a single IC chip, and its function is quite small and small. Because the single-chip structure is

simpler than the general-purpose microcomputer, the price is lower and the development is easier,

so it is used in industrial control and home appliances, also known as microcontrollers. The

laboratory aims at the principle and application of a single-chip microcomputer, using Arduino and

Raspberry Pi as the control platform, using IDE and Python The compiler is used as a programming

tool, combined with various sensor components, so that students can learn the use of sensor

hardware from a single-chip microcomputer to strengthen software programming skills, and

combined with 3D printing technology, to cultivate students' ability to produce special topics. |

| Teaching Objectives: |

| 1. |

To enable students to understand the structure and principles of a single-chip microcomputer

and the syntax of its programs. |

| 2. |

The internship explores the different application circuits and programming skills of a single

chip. |

| 3. |

Tutor students to obtain a single-chip C certificate or above to enhance students'

competitiveness. |

|

| A full view of the laboratory |

|

| Instruments and equipment |

| In terms of instruments and equipment, the laboratory has 32 personal computers, digital

oscilloscopes, signal generators, power supplies, heat guns, Arduino control boards, Raspberry Pi

control boards, and single-chip microcomputer simulationsIn addition to the research equipment

such as burners, there are also professional processing areas, circuit board production areas,

electronic circuit welding testing areas and parts and material warehouses, supplemented by the

latest mechanical and electronic drawing wiring and circuit board design software, so that the

laboratory can fully meet the needs of teachers and students in the department from design,

production to assembly of research and development tools, environment and capabilities. |

|

| Research Results |

|

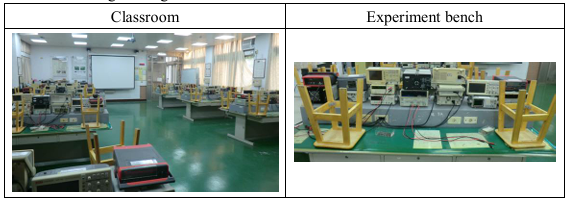

Electronics laboratory |

| This laboratory aims to cultivate students' understanding of electronic

components , familiarity with instrument operation, establishment of electronic

circuits, confidence in independent work, and comparison of electronic principles and

experiments , so that theory and practice can be mutually confirmed, and used to

inspire research and thinking, as well as the ability to troubleshoot, to gain a clearer,

deeper and more specific understanding of practice. |

| laboratory equipment: |

|

| Electronic circuit experiment: compulsory course for the daytime department and

compulsory course for the continuing education department of the Department of

Mechanical Engineering |

|

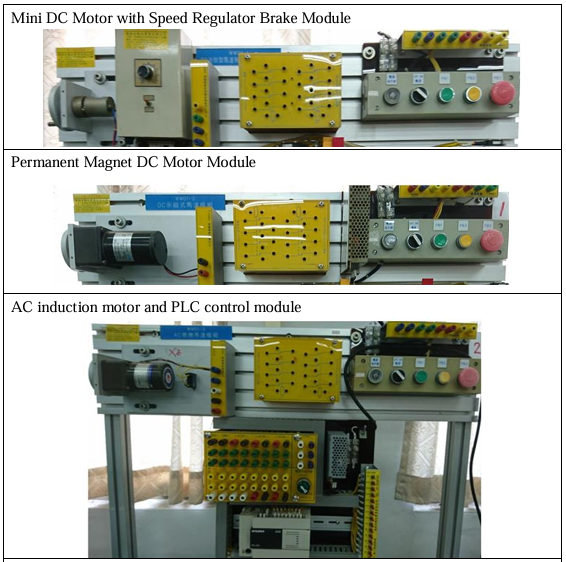

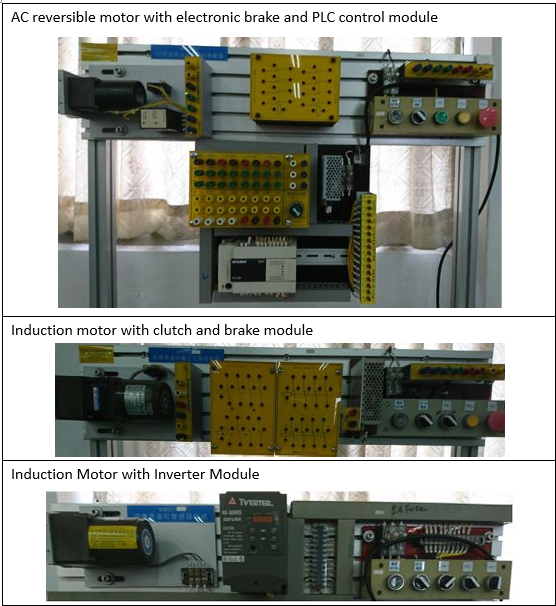

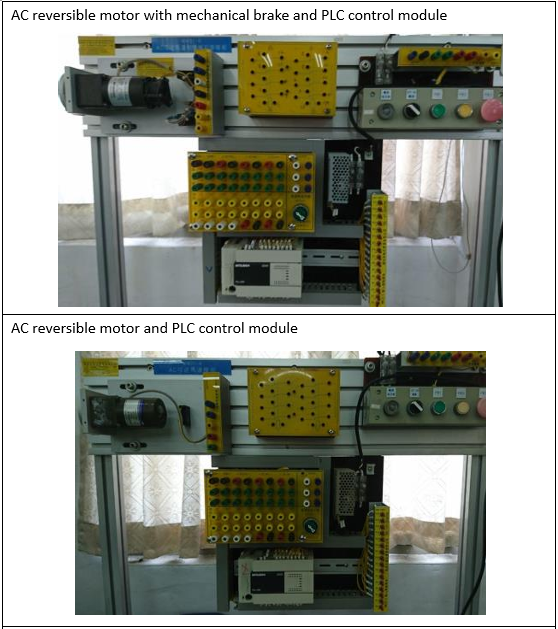

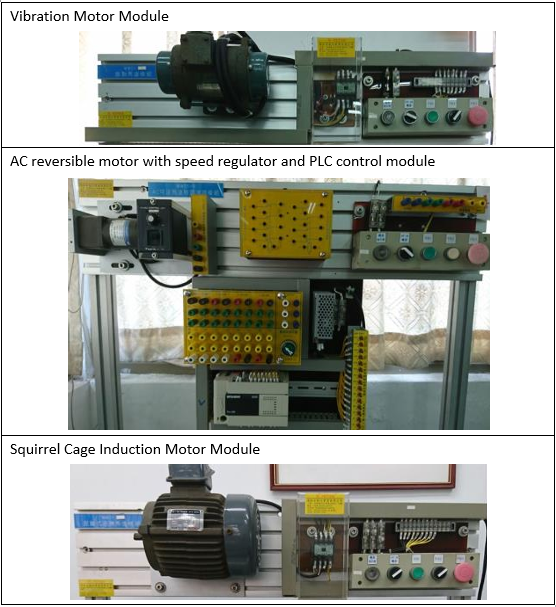

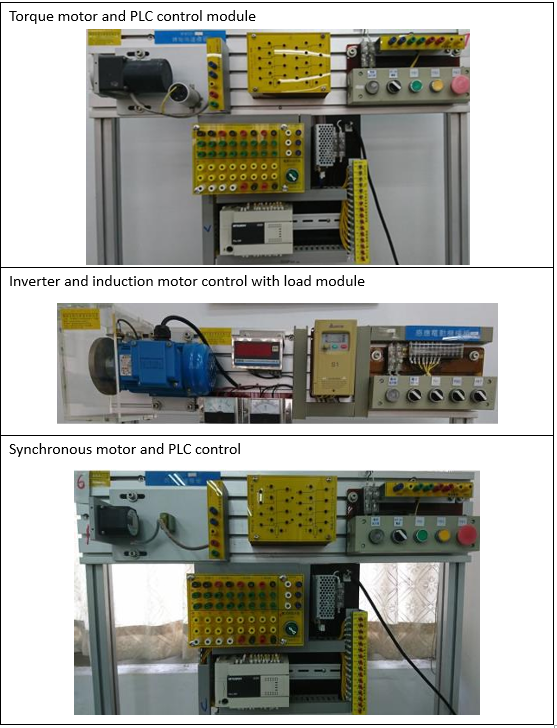

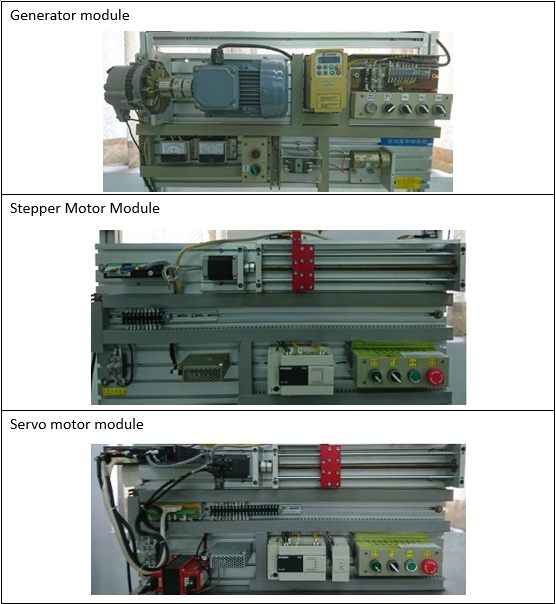

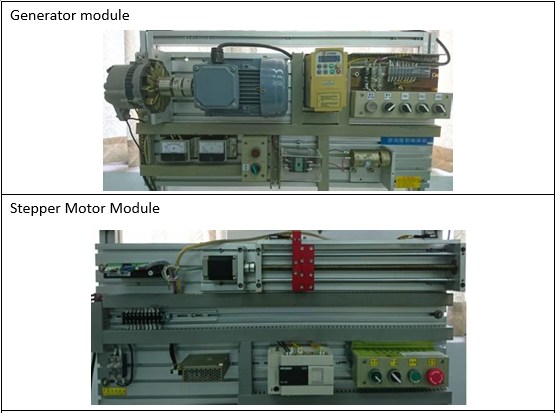

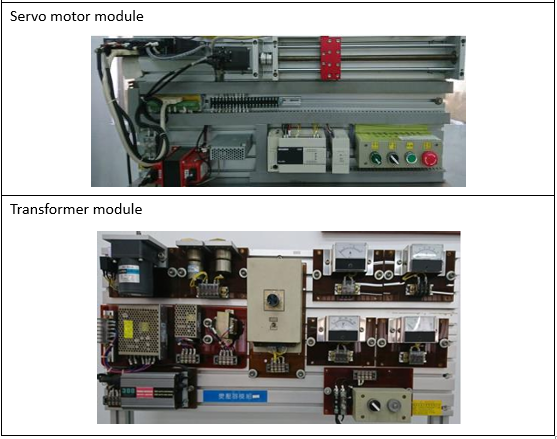

Electrical Machinery Laboratory |

| This teaching laboratory provides space and equipment suitable for general

industrial motors and generators, PLC control, and wiring practice. Through course

training and hands-on practice, students are cultivated to have the ability to design

PLC and integrate peripheral systems, verify the theoretical knowledge learned in the

classroom, and enhance practical ability and experience. Cultivate electromechanical

practical control talents for the industry. |

| Teaching objectives: |

| 1. |

Let students understand the functions, uses, structures, specifications, etc. of

various motors. |

| 2. |

Cultivate students with various motor and PLC control and wiring skills

EquipmentS: |

|

|

|

|

|

|

|

|

|

| Classroom |

|

Introduction to the locomotive practice factory, and introduction to the laboratory |

| With the rise of computer technology in recent years, traditional carburetor motorcycles are

facing elimination, and the era of full computerization has arrived. The demand for computer

diagnosis and repair and signal analysis and diagnosis talents is very urgent, especially in Taiwan,

which is a country with a high density of motorcycles (speed cars). The technology of using

computers for diagnosis involves basic principles such as basic electricity, electronics, and electrical

engineering. The main function of this laboratory is to use computer diagnostic equipment to

provide all the basic concept courses required for computer diagnosis. Through the training of

diagnostic courses, it provides the motorcycle repair industry with the talents needed in the future.

The laboratory is also the training location for the "Motorcycle Repair" Level B and C courses. It is

equipped with the latest diagnostic equipment and fully meets the requirements of candidates. It

guides students to obtain the Motorcycle Repair Level B and C certificates and helps students

successfully obtain the certificates |

| Teaching objectives: |

| 1. |

To enable students to understand the skills and knowledge of the following internship projects:

such as locomotive electrical system starting, charging, lighting, signaling, etc.

Component identification, resistance measurement, circuit measurement and repair,

troubleshooting, etc. |

| 2. |

To familiarize students with the control functions of various components through diagnostic

testing. |

| 3. |

Cultivate students’ proper professional ethics and work attitudeTeaching objectives |

|

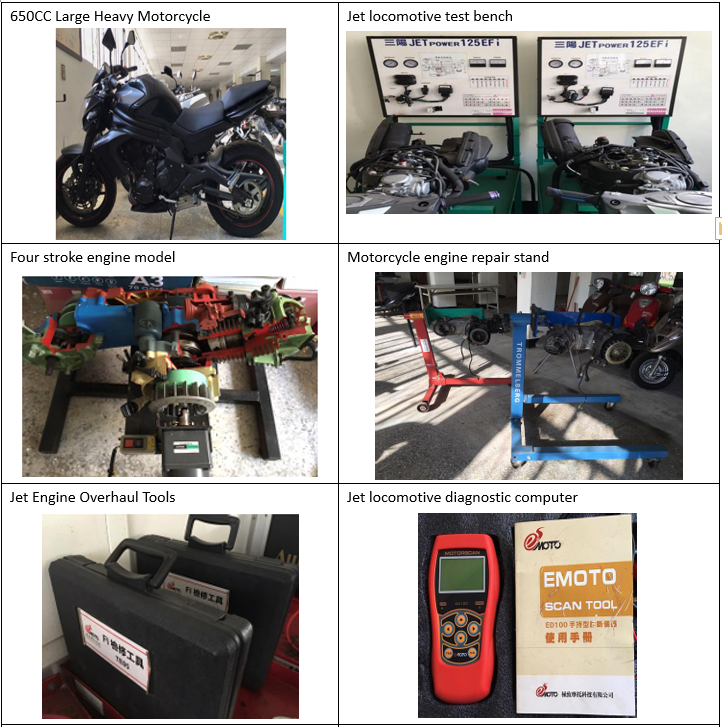

| Instruments and Equipment |

| Device Space Name |

Quantity |

| dengen/HR-MAX70D/1 Full-wave rectifier

fast charger |

1 |

| QROTECH/QRO-201 Two-Gas Exhaust

Analyzer |

1 |

| EMOTO/ED-100 Diagnostic Instrument |

1 |

| Jet engine fuel pressure gauge |

2 |

| DET-610 Tachometer |

3 groups |

| Nine-in-one motorcycle diagnostic instrument |

2 sets |

| Four-stroke jet locomotive engine anatomical

model |

1 Group |

|

| Laboratory Overview : |

|

|

| subject |

Course Title |

class |

Course Overview |

| 1 |

Locomotive inspection

practice |

Grade 3 of the

fifth-year

college Grade

4 of the fifth

year college |

Motorcycle repair and maintenance

Class B tutoring Motorcycle jet

engine repair Electronic jet sensor

principle and detection

|

| 2 |

Locomotive Principles

and Practice |

Grade 1 |

Motorcycle repair and

maintenance level C tutoring

Motorcycle component

disassembly and assembly

Motorcycle component

measurement |

|

Introduction to Automobile Engine Internship Factory |

| Laboratory introduction |

| In recent years, with the rise of computer technology, traditional old-fashioned cars are facing

elimination, and the era of comprehensive new technology has arrived. |

| 1. |

.The demand for talents in brain diagnosis, repair and signal analysis is very urgent,

especially as Taiwan is a country with a high density of automobiles Brain-based diagnosis

technology involves basic principles such as basic electricity, electronics, and introduction

to electrical engineering, and the main function of this laboratory is |

| 2. |

.It is a course that uses computer diagnostic equipment and all the basic concepts

required for diagnosis of various instruments. Through the training of diagnostic courses,

it provides |

| 3. |

The auto repair industry provides the talent needed for the future. This laboratory is also

a training venue for the Level C course of "Car Maintenance", equipped with

The new diagnostic equipment fully meets the requirements of candidates. It helps

students obtain the Class C automobile maintenance certificate and helps them

successfully pass the examination. Obtain the certificate. |

|

| Teaching objectives: |

| 1. |

Let students understand the skills and knowledge of the following internship projects: such as

identification of components such as starting, charging, lighting, and signals in the automotive

electrical system.

Resistance measurement, circuit measurement and repair, component disassembly and assembly,

full vehicle maintenance, etc |

| 2. |

Make students familiar with the functions, structures and disassembly and assembly skills of

each component. |

| 3. |

Cultivate students’ proper professional ethics and work attitude.

Laboratory location |

|

| Instructor Lin Dequan |

| Equipment |

Quan. |

| Ultra-thin flat-type jacking |

2 units |

| Four wheel jack |

1 set |

| Tool cart set |

1 set |

| Injection engine fuel pressure gauge |

1 set |

| Current hook meter |

1 set |

| Cylinder compression pressure gauge |

1 set |

| Water tank pressure gauge |

1 set |

| Car computer diagnostic tool V70 |

1 unit |

|

|

| Offer courses |

| subject |

Course Name |

Class |

Course Overview |

| 1 |

Automobile

Maintenance Internship

(V) |

Comprehensive

Fifth-year |

Automobile Maintenance Level C

Tutorial

|

| 2 |

Car Maintenance Level

C Promotion Class

Car maintenance level

C coaching |

Automotive

component

disassembly

and assembly |

Automotive component

measuremen

|

|

Introduction to Automobile Engine Internship Factory |

| Laboratory introduction |

| In recent years, with the rise of computer technology, traditional old-fashioned cars

are facing elimination, and the era of comprehensive new technology has arrived. The

demand for talents in brain diagnosis, repair and signal analysis is very urgent,

especially as Taiwan is a country with a high density of automobiles. Brain-based

diagnosis technology involves basic principles such as basic electricity, electronics,

and introduction to electrical engineering, and the main function of this laboratory is

It is a course that uses computer diagnostic equipment and all the basic concepts

required for diagnosis of various instruments. Through the training of diagnostic

courses.The auto repair industry provides the talent needed for the future. This

laboratory is also a training venue for the Level C course of "Car Maintenance",

equipped with The new diagnostic equipment fully meets the requirements of

candidates. It helps students obtain the Class C automobile maintenance certificate

and helps them successfully pass the examination. Obtain the certificate. |

| Teaching objectives: |

| 1. |

Let students understand the skills and knowledge of the following internship

projects: such as identification of components such as starting, charging, lighting,

and signals in the automotive electrical system. |

| 2. |

Resistance measurement, circuit measurement and repair, component disassembly

and assembly, full vehicle maintenance, etc. |

| 3. |

Make students familiar with the functions, structures and disassembly and

assembly skills of each component. |

| 4. |

Cultivate students’ proper professional ethics and work attitude. |

|

| Equiments: |

|

|